Author: OrderPlastics

2024-06-26

LAPP launches ETHERLINE FD bioP Cat.5e, its first cable in series production made from bio-based materials. The TPU jacket of this Ethernet cable is made from 43% renewable raw materials (according to ASTM D6866). Compared with conventional fossil-based TPU jackets, it has the same product properties but reduces the carbon footprint by 24%.

According to Marc Jarrault, Managing Director of LAPP India: "This innovative cable is partly bio-based, reducing the carbon footprint and offering customers a sustainable option without compromising performance. LAPP is currently focusing on improving the sustainability of cable jacket materials and promoting the use of bio-based polymers."

Last year, LAPP already presented the first prototypes of cables with bio-based jackets at the Hannover Messe. "Sustainable materials are now much more expensive due to the complex manufacturing process. Therefore, it is important for us to know whether our customers are also willing to invest in sustainable products. Customers are very interested in this. LAPP is currently producing ETHERLINE FD bioP Cat.5e in series."

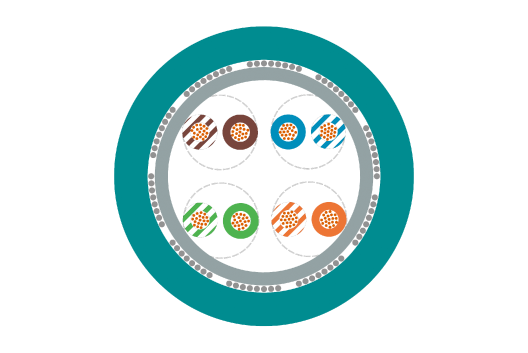

The cables with fossil-based or bio-based jackets are suitable for patch cord structures up to 60 meters in length and are particularly suitable for demanding applications: such as continuous moving use in cable chains, moving machine parts and EtherCAT and EtherNET/IP applications. Thanks to its Cat.5e performance of up to 1000 Mbit/s, ETHERLINE FD bioP Cat.5e enables lightning-fast information exchange and is used to transmit analog and digital signals in the frequency range of up to 100 MHz. The copper braid has a high coverage rate and ensures optimal protection against electromagnetic interference. Halogen-free and flame-retardant materials reduce possible dangers in the event of a fire.

In addition, the bio-based TPU sheath is not affected by mineral oil-based lubricants and is chemically resistant in many cases. The highly flexible Cat.5e Ethernet cable has successfully passed more than 1 million bending cycle tests at LAPP's own test center. This cable has obtained UL/CSA certification based on technical data and can be used in North America.

It is reported that this TPU cable sheath uses BASF's thermoplastic polyurethane Elastollan N. Elastollan N is a corn-based biopolymer. Depending on the type of TPU, the proportion of renewable raw materials is 45% to 60%. This TPU has the same durability, flexibility, mechanical properties and resistance to hydrolysis, chemicals and UV rays as conventional Elastollan. Even the processability parameters are retained. Of particular note is that the proportion of organic material in the finished product can not only be verified but also precisely measured (according to ASTM D 6866).

Finally,

Our mainly materials including SABIC, SOLVAY, BASF, VICTREX, ARKEMA, DAIKIN, CHEMOURS, AGC brands with Fluoroplastics TP/PI PAI PEEK PEI PPSU PSU PES PP Compound to widely used in various fields, such as energy equipment, electronic, automotive, household appliances, etc.

If you also want to find a good and stable supplier for long term, you can make a try order to compare everything details. Believe we will your the right choice!

Welcome check to: www.orderplastics.com

Contact: Sunny Lee

Phone: +86-18923346780

E-mail: xe001@hearplastics.com

Whatsapp:86-18923346780

Add: No. 951#, Gudu road, Sanxiang Town, Zhongshan Guangdong Provice, China

We chat