Recently, Arkema and IEMAI Intelligent have officially reached a partnership to jointly provide users with 3D printing solutions for high-performance Kepstan® PEKK materials, helping users quickly obtain PEKK printed parts with better dimensional stability and higher Z-axis strength.

IEMAI Intelligent is a high-tech enterprise in China that focuses on 3D printing research and development and production. IEMAI3D is a global industrial 3D printer brand that is committed to providing users with multi-material compatible "Allinone" 3D printing solutions that support printing most thermoplastic materials on the market. IEMAI Intelligent's 3D printing solutions have been applied to: aerospace, automotive, petrochemical, medical and electronic manufacturing industries.

PEEK performance:

PEKK is another polymer in the polyaryletherketone (PEAK) family and one of the highest performing polymers in the world. PEKK has excellent mechanical, heat and chemical resistance, but is easier to print than PEEK. Compared to PEEK filaments, PEKK can be processed at lower 3D printing temperatures and has excellent layer adhesion, resulting in parts with excellent dimensional accuracy and Z-strength.

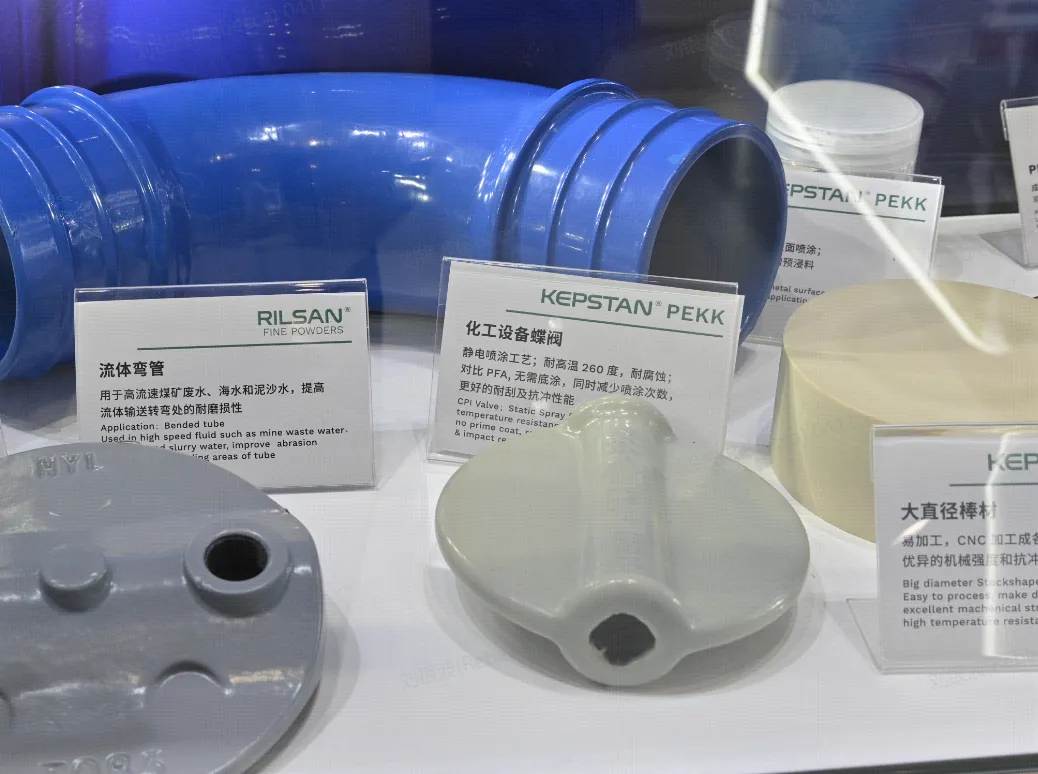

PEKK can replace metal and composite parts in a variety of industries, including aerospace, automotive, medical technology and marine.

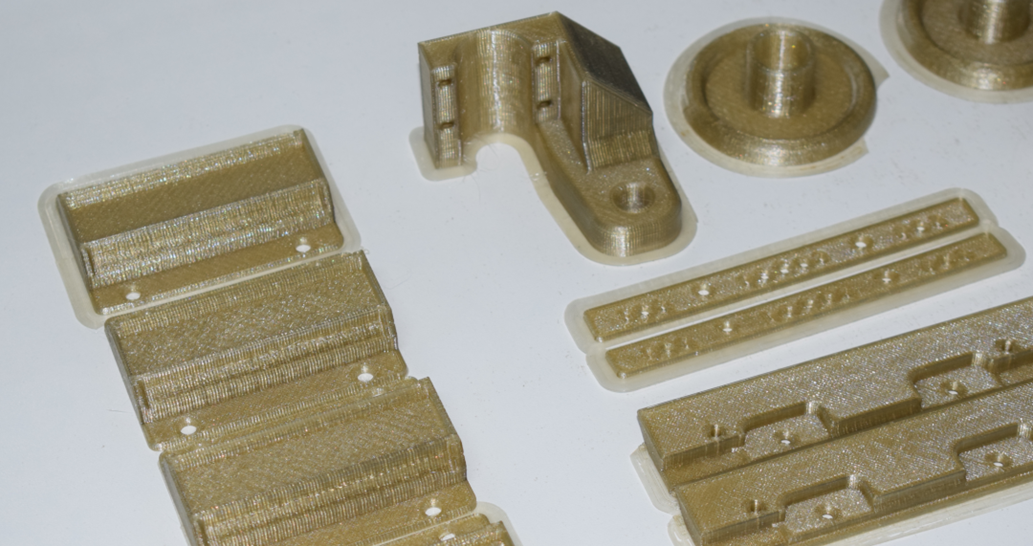

Parts printed with PEKK can be heat treated (annealed) after printing to maximize mechanical, thermal and chemical resistance. The color of the printed parts is transparent golden yellow, which turns to opaque tan after annealing.

Features:

High temperature resistance up to more than 255ºC

Extreme stiffness, tensile and compressive strength and impact resistance

Easy to print

Flame retardant, low off-gassing

Very limited warping

Resistant to almost all organic and inorganic chemicals

Arkema has acquired PEKK production technology capabilities after completing the acquisition of the US company Oxford Performance Materials (OPM) in 2009. In close cooperation with the chemicals company PCAS, Arkema has opened the first PEKK industrial production plant in Europe in France and is building a second, larger PEKK production plant in the United States. Trade name: Kepstan® PEKK.

Kepstan® PEKK has an extremely high melting point (300°C to 360°C, depending on the grade) and excellent chemical and abrasion resistance. When reinforced with carbon fiber, it is as hard as some metals but much lighter. It is non-flammable and does not produce toxic gases. It is also easy to shape above its melting point. Traditionally, it can also be injected into molds or extruded to produce pipes or films.

One of the largest global applications of Kepstan® PEKK is composite materials used in aerospace. In addition, PEKK is also present in the oil and gas, automotive and transportation, general industry, 3D printing and consumer electronics industries, providing high temperature and corrosion resistant material solutions for various applications.

OrderPlas is high-temperature Plastic Raw Material and special material's China supplier.

We also can be supply you the ARKEMA all series materials including KEPSTAN PEKK, Kynar PVDF, Pebax Series, Rilsamid PA12, Rilsan PA11 and so on.

More details please check to: https://www.orderplastics.com

Contact: Sunny Lee

Phone: +86-18923346780

E-mail: xe001@hearplastics.com

Whatsapp:86-18923346780

Add: No. 951#, Gudu road, Sanxiang Town, Zhongshan Guangdong Provice, China

We chat